Maintaining the same passion and mastery of the past, the company has specialised in highly avant-garde products that gives life to an increasingly trendy, comfortable, ecologically sustainable, formal and casual shoes.

In fact, in recent years, Lancio has transmitted its artisan roots to a completely new, less formal but equally attractive lines and today they are important part of the luxury-sports collection.

The master shoemakers and Lancio designers have always collaborated to create a shoe that, with personality and elegance, brings an impeccable look and guarantees foot comfort at all times.

The Lancio shoe factory has all the necessary experience and knowledge of the most shoemaking techniques, finding them in a mix of expertise and doses of tradition and innovation.

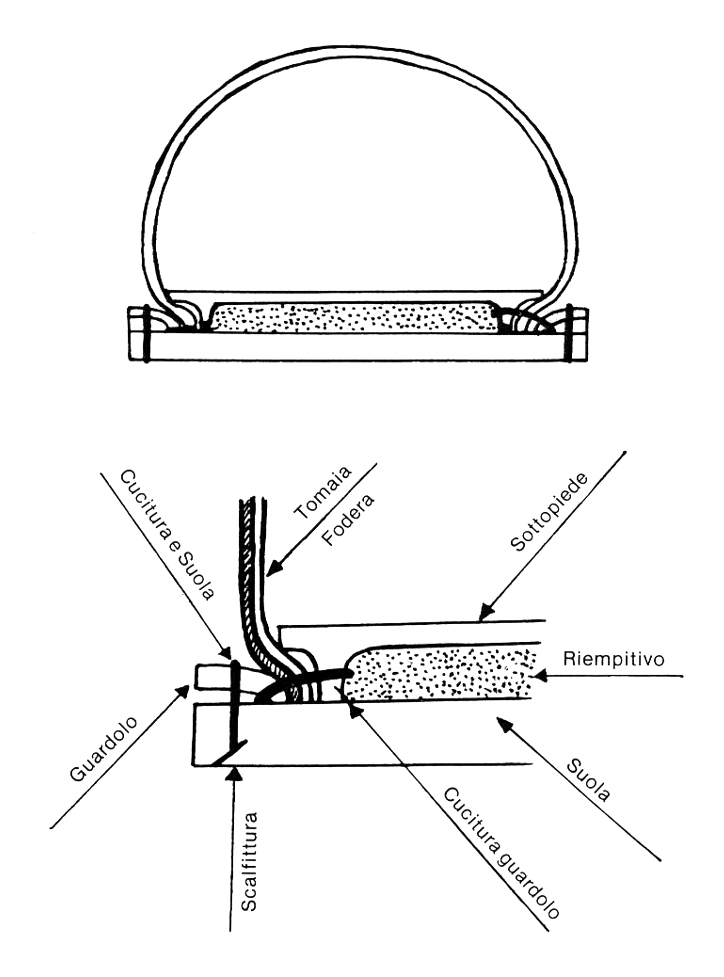

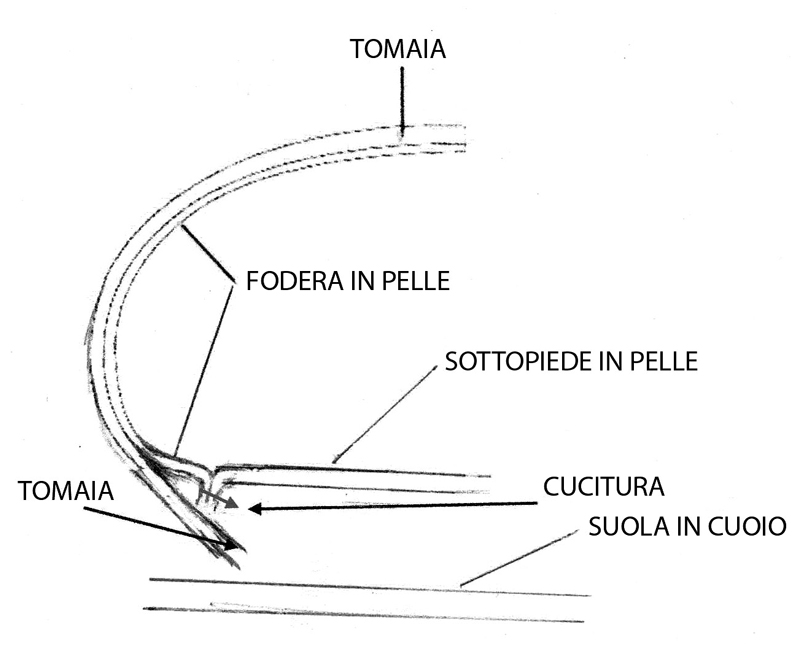

It is an old process and bears the name of the inventor Charles Goodyear, the manufacturing consists of two seams, the first joins the insole to the upper and the welt, the second the welt to the sole.

The insole is normally reinforced with fabric.

The “Goodyear” seam is a very slow process that requires great manual skill, for this reason it is considered the most esteemed manufacturing. In this system, the various parts are not perforated and the greatness of the work consists precisely in the seam section made meticulously by the craftsman. In this case the seam is not visible inside.

This process defines a resistant but at the same time soft and flexible shoe.

The upper is prepared with the outer edges glued and pressed on a special midsole and then stitched; cotton thread is first passed in a specific boiler, where melted pitch, guarantees the water resistance of the thread and the holes.

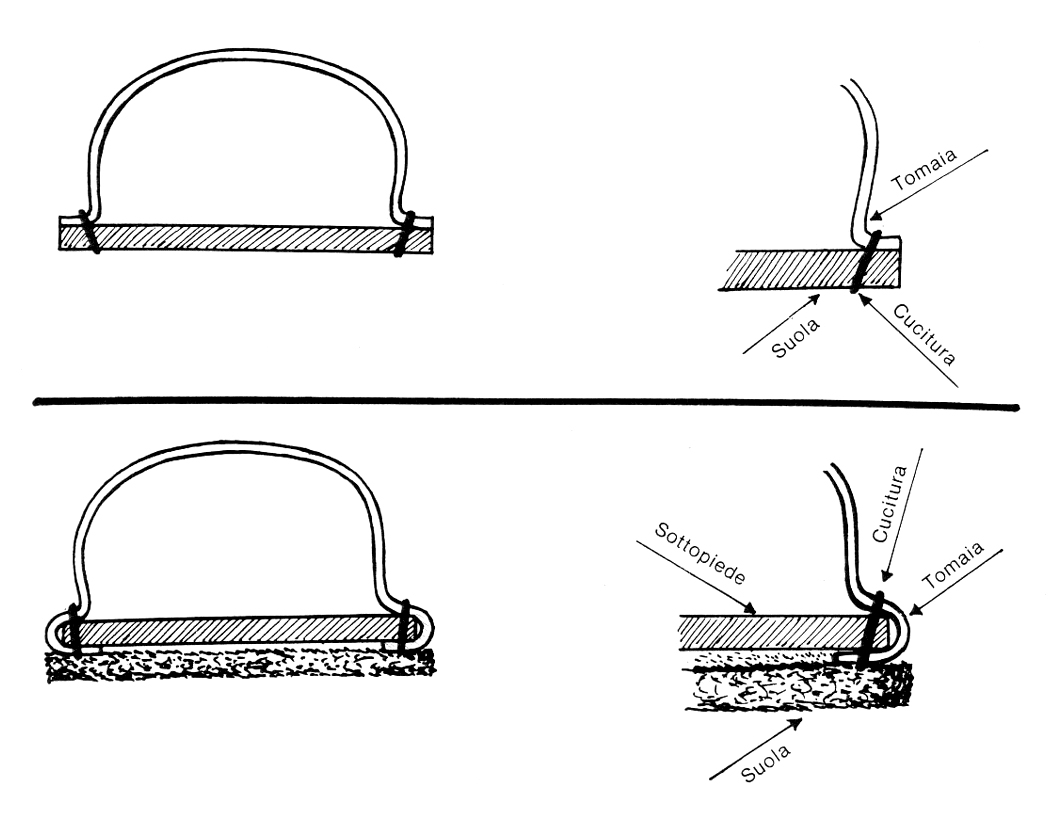

This system presents a much simpler variant which consists in turning the edges of the upper outwards by mounting them directly on the sole.

Particularly suitable for summer footwear such as sandals . It gives the shoe lightness and flexibility. It is possible to apply variants, that allows thick and winter sole to be used (for example rubber).

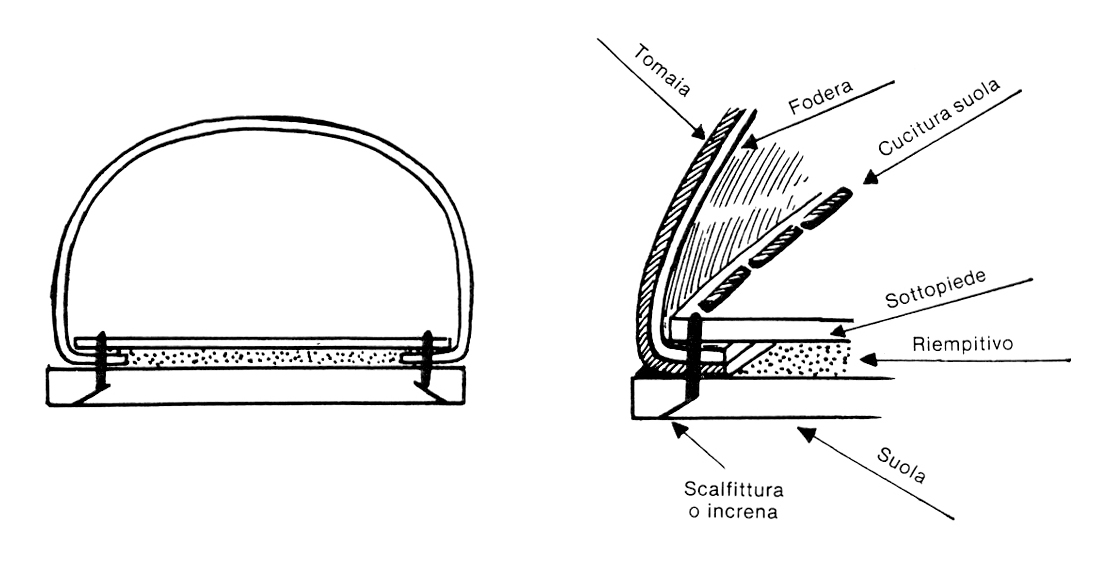

The Blake process bears the name of the inventor of the machine that sews inside and outside. To sew the sole it is necessary to remove the last and re-insert it for the finishing operations. Such seam is visible on the insole.

This type of processing makes the shoe flexible and resistant.

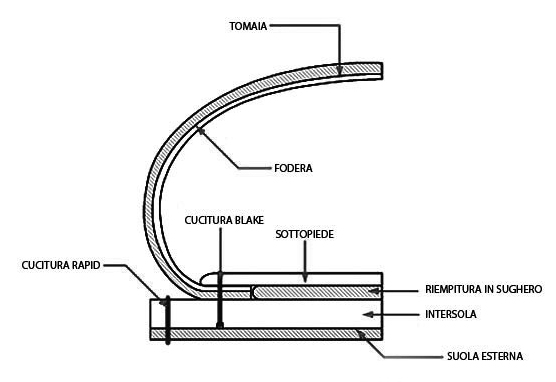

Blake-Rapid is a combination of Goodyear method and Blake, is one of the oldest construction techniques and is characterised by two stages: the first Blake (inner seam) joins the upper, insole, lining and midsole . The second external seam ( Rapid ) binds the midsole to an additional layer of leather, which forms the final bottom of the shoe.

Advantages: the Blake Rapid construction gives the possibility to resole the shoes, it is often used in winter footwear, it makes the shoes comfortable, waterproof and long lasting.

Not all models are suitable for this type of construction, it is ideal for slippers and simple summer shoes. The upper is sewn to the insole together with the band which then covers the wedge. For this process, the upper is not mounted on the last, but simply inserted. Therefore, if the model is not perfect, the defects can only be eliminated with heat treatment.

Advantages: the sacchetto process guarantees maximum softness, lightness and comfort.